MACHINE TECHNOLOGY

Information about possibility of cooperation, machine technology and used machines.

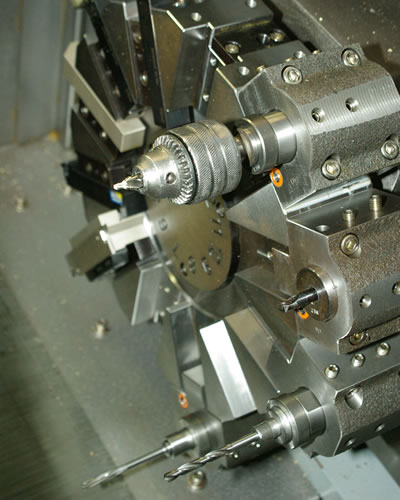

Complex production possibilities

Hydrex holds strong position among engineering companies in region. Even in the past, the production of gears and planetary gears dominated by Hydrex, which is the main part of the production portfolio.

The beginning of the production process is the technological preparation of the production together with the design and programming of the software SOLIDWORKS and SOLIS CAM. We also have the right conditions for prototype production and development of new products. In 1998, we were certified according to ISO 9001. Since then, production has been carried out according to the quality management principle. For this, the Wenzel 3D measuring instrument is also used, which together with special software is an important production control mechanism and ultimately ensures the satisfaction of our customers.

Modern Machines

CNC Horizontal lathes and milling machines

| Type – Made by | Max. Diameter of Machining (MM) | Max. Length (MM) | Max. weight (KG) |

| S-50i – Mikron | 320 | 500 | |

| SBL-500 – Trens | 405 | 750 | 220 / 420 |

| QDC3 5M – Leadwell | 600 | 1030 | Hrot – 700 |

| MCV1000 Speed – Leadwell | 800 | 2035 | Hrot – 1200 |

CNC Vertical Lathes (Karusel)

| Type – Made by | Max. Diameter of Machining (MM) | Max. Length (MM) | Max. weight (KG) |

| SKJ 8 EN – Toshuin | 630 | 300 | 2500 |

CNC 3-axes Vertical Centers

| Type – Made by | Range of Motion x/y/z (MM) | Distance Spinle-Table (MM) | Max. weight (KG) |

| VMC1005 – Pinnacle | 1020/610/610 | 100 – 710 | 850 |

| QMBC – 25 – Pinnacle | 2000/900/850 | 150 – 1000 | 3000 |

CNC 4-axes Vertical Centers

| Type – Made by | Range of Motion x/y/z (MM) | Distance Spinle-Table (MM) | Max. weight (KG) |

| MCV1270 Power | 1270/710/6120 | 100 – 720 | 1200 |

CNC 5-axes Vertical Centers

| Type – Made by | Range of Motion x/y/z (MM) | Distance Spinle-Table (MM) | Max. weight (KG) |

| QMBX700 – Pinnacle | 1400/710 /680)/810 | 100 – 720 | 1200 / 1000 |

CNC 4-axes Horizontal Centers with 2 Tables

| Type – Made by | Range of Motion x/y/z (MM) | Distance Spinle-Table (MM) | Max. weight (KG) |

| QMBH-500B – Pinnacle | 650/560/560 | 50 – 100 | 400 |

CNC Horizontal and Boring Centers

| Type – Made by | Range of Motion x/y/z (MM) | Distance Spinle-Table (MM) | Max. weight (KG) |

| QBMH – Sanco | 1500/1180/1000 | 50 – 100 |

NC grinding machines (for flat and round blades)

| Type – Made by | Range of Motion x/y/z (MM) | Size of Magnetic Table (MM) | Max. weight (MM) |

| QOCP1640 – Equiptop (flat) | 500/1000/500 | 400 – 1000 | |

| QMBC – 25 – Pinnacle (round) | 1000/900/850 | 150 – 1000 | 15350/420-380 |

NC Cut Machines for Gearwheel

| Type – Made by | Head Diameter x, y (MM) | Min. Head Diameter x, y (MM) | Max. weight (KG) |

| OHA CNC5 – TOS Čelakovice | 500 | 50 | 150 |

| OFA 32 CNC6 – TOS Čelakovice | 320 | 40 | 250 |

Horizontal Boring Machine

| Type – Made by | Range of Motion x/y/z (MM) | Diameter (MM) | Max. weight (KG) |

| W100-A – TOS Vansdorf | 1600/1120/900/1250 | 100 | 300 |

Would you like to know more information about our products? Look at our machining catalogue with simples of few ones

Our Service

We offer complete service in engineering.

The production of Hydrex will provide you the complete construction and technological preparation according your needs.